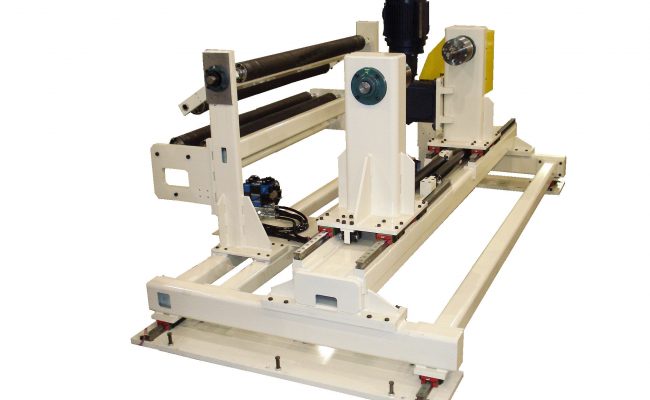

Unwinds and Rewinds

Retroflex specializes in engineering and manufacturing standard and customized unwinds and rewinds for various applications. They offer a broad range of solutions, ranging from straightforward single-spindle modules to advanced turret systems equipped with automated splicing and transfer capabilities.

Their dedicated in-house engineering team possesses extensive experience and can tailor winders to handle a diverse array of substrates, spanning from lightweight films to heavy-duty paperboard, and can operate at virtually any desired speeds.

Retroflex Unwinds & Rewinds

Unwinds and Rewinds

Retroflex’s winders are designed with flexibility in mind, allowing them to accommodate a wide spectrum of web widths, roll diameters, and core sizes. Additionally, they offer custom slitting systems suitable for both shear and razor slitting operations.

Each Retroflex winder is supplied with comprehensive component assembly drawings and operational manuals to ensure smooth setup and use.

Typical Unwind Features

- Shaft type models include safety chucks for fast, easy and tool free core shaft changes.

- Disk type brakes can be dancer or transducer roll regulated for precise tension control.

- Auto side shifting of the entire unwind for web guiding is available. The unit can be mounted to precision linear slides and is shifted via a single edge guide and electro-mechanical guiding system. Separate pivoting style web guides are also available.

- Shaft type models include pneumatic core shafts for fast core changes.

- Unwinds can be center braked, center driven or surface driven.

Typical Rewind Features

- Shaft type models include safety chucks for fast, easy and tool free core shaft changes.

- Shaft type models include pneumatic core shafts for fast roll changes.

- Slitter systems are custom designed to suit your needs.

- Variable bow spreader rolls are available for web separation after slitting. These rolls can be driven if required.

- Pneumatically loaded lay-on rolls are available.

- Driven pull roll sections are available to suit your needs.

- Rewinds can be center or surface driven or a combination of both.

Complete Your Line With Quality Unwinds & Rewinds

- Single Spindle and Turret Winders

- Phantom Axis Systems

- Floor Loading Systems

- Cantilever Designs

- Narrow Web to Wide Web Systems

- Light to Heavy Weight Webs

- Various Drive and Braking Options

- Precision Tension Control Features

- Web Transfer and Splicing

- Web Guiding Via Auto Side Shifting or In-Line Pivoting Systems

- Shafted Designs with Safety Chucks and Air Shafts

- Shaftless Designs

![]()

Bingham Flexo Services is a proud sales partner for Retroflex flexo press systems.

Available Brochures

- Unwinds and Rewinds

Markets & Applications

- Narrow Web Flexo

- Mid Web Flexo

- Wide Web Flexo

Contact Bingham Flexo Today

For More Information

630-879-7301

Or Email Us At

info@binghamflexoservices.com

For More Information

630-879-7301

Or Email Us At

info@binghamflexoservices.com