Rubber Feed Rollers, Wipe & Applicator Rolls

Urethane and Rubber Feed Rollers and Sleeve Product Offering

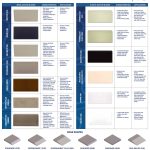

Bingham Flexo Services partners with top-tier suppliers to provide high-quality rubber feed rollers and sleeves for flexographic printing. Our rubber elastomer and cast urethane product solutions are designed for durability, precision, and superior performance in various applications. Urethane offers excellent cut and abrasion resistance, while specialized rubber elastomers provide heat resistance, chemical resistance, and optimal ink transfer. Our suppliers manufacture rollers with advanced features such as dual durometer, custom grooving, crowns, and high-finish specifications. With our application expertise, we help you select the best rubber feed rollers to meet your specific production needs.

Corrugated Box Applications

Bingham Flexo offers urethane, nitrile and neoprene wipe and feed rollers manufactured by two companies specializing in corrugated supply. We understand the importance of the proper covering, durometer, diameter, crown and grooving. Our suppliers have many OEM prints and have supplied rollers to many of the corrugated OEM’s

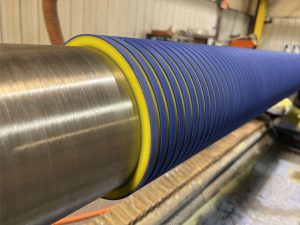

DuraFeed dual durometer urethane is the recommended covering for corrugated feed rollers. The benefit is extended life and reduced board crush. This is possible due to a soft 30 durometer inner layer topped with a .030” thick 65 durometer outer layer. Overall hardness is approximately 40 durometer. Others offer dual durometer, but their outer layer is so thick that overall durometer is typically 50+. Also offered is a 35 durometer urethane rubber option for price conscious applications. Urethane is preferred due to its extremely good abrasion and cut resistance when compared to any rubber elastomer

DuraFeed dual durometer urethane is the recommended covering for corrugated feed rollers. The benefit is extended life and reduced board crush. This is possible due to a soft 30 durometer inner layer topped with a .030” thick 65 durometer outer layer. Overall hardness is approximately 40 durometer. Others offer dual durometer, but their outer layer is so thick that overall durometer is typically 50+. Also offered is a 35 durometer urethane rubber option for price conscious applications. Urethane is preferred due to its extremely good abrasion and cut resistance when compared to any rubber elastomer

Urethane, nitrile and neoprene are available at any specified durometer, diameter and length. The rollers are then ground and polished straight, or with the specified parabolic (barrel) crown. We can assist with crown recommendations by performing nip impression testing to help specify the correct crown for your roller diameter and length

Urethane, nitrile and neoprene are available at any specified durometer, diameter and length. The rollers are then ground and polished straight, or with the specified parabolic (barrel) crown. We can assist with crown recommendations by performing nip impression testing to help specify the correct crown for your roller diameter and length

Printing Applications

Bingham Flexo supplies both rollers and sleeves that are rubber covered and laser engraved for specialty printing and spot coating applications. We can help select the best material and can offer a one stop shopping experience. Roller or sleeve, covering and engraving all from the same source. No finger-pointing, just service and performance.

Laser engraved rubber coverings outlast and outperform photopolymer in terms of life and chemical resistance. Enhanced laser engraving techniques have also escalated the print performance from laser engraved rubber in recent years. Do you have an application where you would like to see longer life? Give our rubber rollers or sleeves a try.

Laser engraved rubber coverings outlast and outperform photopolymer in terms of life and chemical resistance. Enhanced laser engraving techniques have also escalated the print performance from laser engraved rubber in recent years. Do you have an application where you would like to see longer life? Give our rubber rollers or sleeves a try.

Coating and Laminating Applications

Coating applications require the tightest roller and sleeve tolerances and finishes. Bingham Flexo partners with companies who specialize in the manufacture roll bases and sleeves and others that offer covering of various rubber elastomers and urethanes. Straight and tapered sleeves are available and tight dimensional and surface finish tolerances are part of our every day supply.

Whether it be a precision manufactured base, straight or tapered sleeve, or selecting the proper covering, BFS and its partners can assist by specifying the correct application, manufacturer, and surface material for your application. Whether it be a tapered sleeve for high nip pressure applications, Hypalon covering for heat resistance, or EPDM for solvent resistance, we can help you find the right product for your application and insure it is manufactured to the tightest tolerances.

Whether it be a precision manufactured base, straight or tapered sleeve, or selecting the proper covering, BFS and its partners can assist by specifying the correct application, manufacturer, and surface material for your application. Whether it be a tapered sleeve for high nip pressure applications, Hypalon covering for heat resistance, or EPDM for solvent resistance, we can help you find the right product for your application and insure it is manufactured to the tightest tolerances.

Markets & Applications

- Wide Web Flexo

- Corrugated Flexo

- Coating & Laminating

Contact Bingham Flexo Today

For More Information

630-879-7301

Or Email Us At

info@binghamflexoservices.com

For More Information

630-879-7301

Or Email Us At

info@binghamflexoservices.com