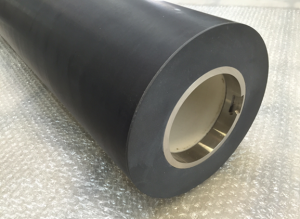

Flexo Plate Mounting Sleeves

Durable, Stable, High Quality Plate Mounting Sleeves for Flexo

Continental Plate Mounting Sleeves

High Quality Flexo Plate Mounting Sleeves

High Quality Flexo Plate Mounting Sleeves

Axcyl® flexo plate mounting sleeves from Continental are designed for all flexo printing applications. The unique honeycomb structure and high quality materials used to produce the Axcyl® product line results in the most stable, durable, and light weight plate mounting sleeves on the market. Specifically engineered for less bounce on press, discover how flexo plate mounting sleeves from Continental can improve your productivity and print quality.

Features & Benefits

Features & Benefits

Features & Benefits

- Easy To Mount – smooth technical fabric interior layer, encased in extremely stable resin.

- Bounce Reduction – proprietary impression dampening layer reduces vibration and press bounce

- Lightweight – honeycomb build-up material for up to 30% weight reduction

- Non Swelling/Stable – carbon fiber or technical fabric and resin construction provide diameter and TIR stability

- Durable – Metal reinforced notches and Hypalon protected ends reduce end damage

Bingham Flexo Services is a proud sales partner for Continental plate mounting sleeves

Markets & Applications

- Wide Web Flexo

- Coating & Laminating

Contact Bingham Flexo Today

For More Information

630-879-7301

Or Email Us At

info@binghamflexoservices.com

For More Information

630-879-7301

Or Email Us At

info@binghamflexoservices.com