Print Inspection & Register Control

Web Viewing & Print Inspection

Using the latest technology, the Matrix print inspection system reproduces the image of the printed web in extremely fine detail, at full production speed. The 16X zoom allows analysis of the print details down to the dot.

- 6 Mega pixel camera resolution assures great image quality and realistic color reproduction

- LED illuminators provides a perfect light distribution for inspection on any kind of substrate, including foil

- Multi-touch monitors guarantee fluency and ease of operation

- The menu driven interface gives the operator full control of the printing functions

- Statistical print inspection

- Automatic ink deck setting (pressure and register for CI flexo)

- Barcode verification

- Color monitoring

- Print repeat measurement and trend display

Front to Back Dual Camera System for Instantaneous Register Comparison

Dual Matrix camera system allows instantaneous display of front and back print for the real time verification of top to bottom register. The system instantly shows the individual images of print side and cold-seal/coating side plus a precise top + bottom overlapped image for the evaluation of the register deviation.

- Continuous scanning of the entire print repeat, through data input of job specifications, print repeat and web width

- Manual and automatic camera movement on preset selected positions

- Camera positioning via icons on the multi touch screen graphic interface

- Camera positioning via icons on the multi touch screen graphic interface

- Internet connection for remote assistance

- Real-time visualization of the front side (print), back side (cold-seal) and overlapping of both

- Optics and illuminators are custom made design to get the best performance on any kind of substrate

Smart Web Viewer

Allows to visualize in real time the printed images (with magnification of the details to dot level) with high performance and quick operations.

- “Full colour” image processing on any type of substrate by using an RGB matrix camera

- Continuous scanning of the whole print repeat

- Up to 32 camera positions storing with possibility to differentiate zoom, iris, and focus for each image

- Camera positioning via icons

- Manual and automatic camera preset in selected positions

- Internet connection for remote assistance

100% Print Inspection

Your customer’s demand for total control is satisfied by our 100% print inspection. The LYNEX assures inspection of the entire print repeat, categorizing and storing every defect detected during production. The system provides this data in roll maps and generates production reports for subsequent analysis and workflow use.

- Real time process analysis, the system operates at web speed up to 1000m/min with clear discrimination of defect by size and type

- 4 K-pixel RGB linear cameras for defect detection down to 0.05 mm, on either printed or unprinted substrates

- 8 K-pixels bi-linear camera

- Job reports and Waste management

- Integration with MATRIX area camera for detailed image investigation when needed

- Real time display of the entire print repeat on a UHD wide screen monitor at full production speed

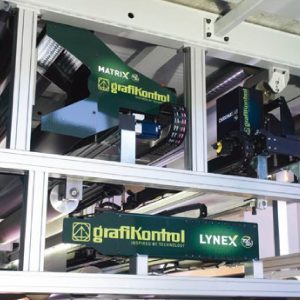

Combination 100% Print Inspection & Web Viewing

The inspection of a wide web cannot be done only with scanning or 100% cameras. Press operators need a tool that combines line scan cameras (LYNEX) and area camera (MATRIX) to guarantee total quality control and to fully satisfiy the customer request for complete process control.

- Full integration of the LYNEX 100% inspection, the MATRIX area cameras and other features are all managed by a single operator interface

- Intuitive multi-touch screen gives quick and easy access to all components and functions

- The area camera and the 100% inspection work independently: the full web inspection is not compromised when press operator uses the area camera for viewing fine print details

- The Touch&View function moves the area camera to a desired position simply by touching a point on the print repeat display screen

Defect Tracking Through Various Processes, Waste Management, & Defect Removal

Newest defect coding system for the traceability of the defects during the entire production process. With this print inspection system, the processing speed and the efficiency of the entire process are increased: thanks to the automatic stops in the slitter the removal of the defects is extremely easy.

- • Size, shape and pattern of the sync-code are programmable

• The size of one sync-code is 2-2.5 mm by 35-40 mm (w x h) and contains Job name, Roll Number and Meterage

• The Ink Jet nozzle (to print the sync-code) is installed on a motorized bar and on the same bar is installed a sync camera that automatically detects the web edge (for auto alignment) guaranteeing a print repeatability and verifies the readability of the sync-code just printed

• The sync-camera reads and transmit the sync-code information to the system in real time for an accurate paring of the detected defects with the roll footage

• The frequency in printing the sync-code is programmable (normally is one sync-code every one or two print repeats)

• When a roll terminates the printing phase a label printer (supplied with the system) generates a label on which a univocal barcode is printed, containing all roll data.

• System is supplied with an editing station to filter the undesired defects, only the selected ones will be removed by automatically stopping the slitter on the sync-code paired with the defect

Transparent Varnish & Coating

Print inspection system to detect defects related to coating processes for varnish, lacquers and cold-seal.

• Clear discrimination of varnish or coating defects from the print ones

• Detection of defects by size and type

• Sensitivity adjustment for each type of defect

• Display of the defect map for each roll in process

• Quality reports for each printed roll

• Database containing 6 months of production

• Manual and automatic preset of the camera in the positions chosen by the operator

• Internet connection for remote diagnostics

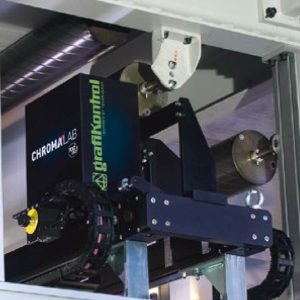

In-Line Spectrophotometer

Provides real time measurement and color correction on start-up and during production.

It can read from either dedicated color patches or the image area itself.

- Provides real time color measurements: spectral curves, ∆E, Lab* values, Density, Dot Gain

- Uses a motorized traverse for automatic positioning on the color bars or directly on selected areas of the image

- Quick color matching: when the measured data is out of specification to the master, the values are sent directly to the ink room where a correction dose is formulated to bring the color back into tolerance

- The system provides an accurate match with all major brands of handheld devices

Color Register Control

The CR33 – CR34 register controls have been developed using the latest electronic and software technologies that, by selecting the best correction algorithm, reduce waste during startups, rampups, splices and re-starts.

![]()

Bingham Flexo Services is a proud sales partner for GrafiKontrol print inspection & register control systems

Markets & Applications

- Wide Web Flexo

Available Brochures

- Print Inspection and Register Control Brochure

Contact Bingham Flexo Today

For More Information

630-879-7301

Or Email Us At

info@binghamflexoservices.com

For More Information

630-879-7301

Or Email Us At

info@binghamflexoservices.com