Flexo Tunnel Dryer Systems

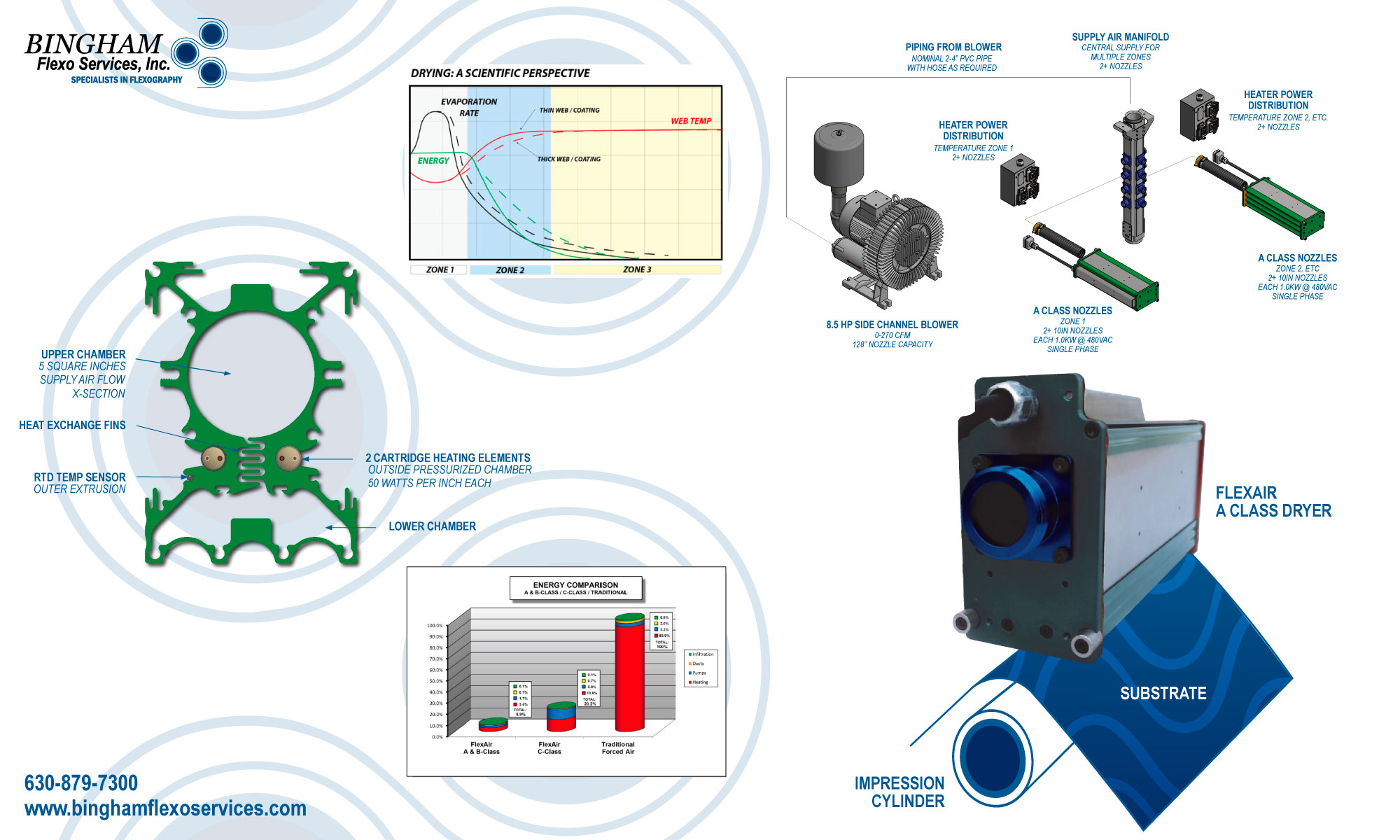

A-Class Flexo Drying Systems

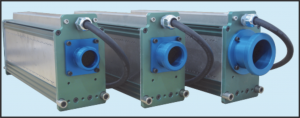

FlexAir’s newest hybrid technology, A-Class flexo tunnel dryer systems features proprietary aluminum extrusions with integrated long-life electric cartridge heaters. Driven by High Pressure Turbo Blower technology, A-Class flexo dryers offer the industry a revolutionary high performance forced air drying solution.

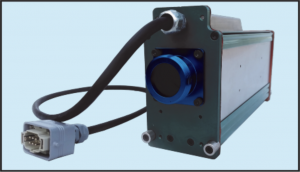

A-Class Nozzles

A-Class nozzles are purpose-built to optimize airflow velocity and thermal consistency across the web. With pre-heated aluminum extrusions and integrated temperature sensing, they provide precise, responsive drying performance in compact tunnel dryer configurations.

Pre-heated aluminum extrusion

Pre-heated aluminum extrusion- Integrated temperature sensor

- Threaded hose connection

- Single phase or 3-phase power

- 6 inch minimum web

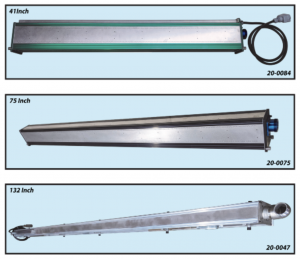

Nozzle Types

A-Class Nozzle: 6 inch minimum

A-Class Nozzle: 6 inch minimum

41 Inch Nozzle: Standard nozzle arrangement

75 Inch Nozzle: No heater arrangement

132 Inch Nozzle: Corrugated printer, Side loading, Cam follower

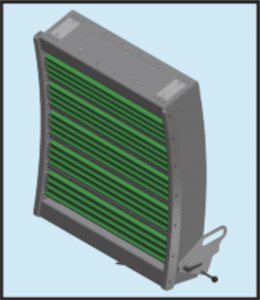

Interstation Dryer

Designed for efficient ink curing between print stations, the FlexAir interstation dryers ensure controlled, high-velocity airflow without compromising web stability. Ideal for film, foil, and paper applications, it supports both water- and solvent-based inks in line and process printing.

INTERSTATION DRYER: 5 Nozzles, Arched web, Idler web support

INTERSTATION DRYER: 5 Nozzles, Arched web, Idler web support- PRESS: MPS EF | 16, 20, 22, 26 inch web

- WEB: Film, Foil, and Paper

- INKS: Water or solvent based

- PROCESS: Line and Process printing

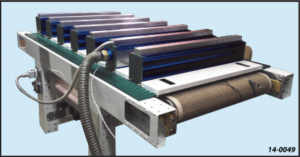

Tunnel Dryer

FlexAir tunnel dryer systems deliver multi-zone, high-efficiency drying for advanced flexographic operations. With flotation capability, flexible air supply configurations, and integrated exhaust systems, they provide uniform heat distribution and reliable performance across a wide range of web widths.

6 Nozzles, 2 Zone

6 Nozzles, 2 Zone- Flotation capable

- Low pressure air supply distribution

- Top or bottom supply air inlet

- 6 Nozzle power distribution (per zone)

- Cantilever mounted

- Platform movable on rails

- Frame integrated exhaust system

Press Specifications

PRESS: Nilpeter FB | 13 inch web

WEB: Paper, Label, and Rigid Film

INKS: Flexo applied and Water based adhesives

PROCESS: Pressure sensitive adhesives converting

Conveyor Tunnel Dryer

Built for coated substrates and rigid materials, the conveyor tunnel dryer offers controlled thermal management for paper, paperboard, and film applications. It is especially suited for digital receptive coatings and gravure-applied water-based inks.

PRESS: Proprietary | 30 inch web

PRESS: Proprietary | 30 inch web- WEB: Papers, Paperboard, and Rigid Film

- INKS: Gravure applied and water based

- PROCESS: Digital receptive coatings

Gravure Coater Tunnel Dryer

Engineered for wide-web gravure coating lines, this multi-zone tunnel dryer delivers precision temperature control and flotation drying for aqueous coating applications, ensuring uniform curing across film and paper substrates in offset gravure processes.

TUNNEL: 12 Side load nozzles, 6 temp zones, Flotation

TUNNEL: 12 Side load nozzles, 6 temp zones, Flotation- COATER: Gravure

- WEB: 63 inch, Film or Paper

- COATING: Aqueous digital receptive coating

- PROCESS: Offset Gravure

Gravure Laminating Tunnel Dryer

Designed specifically for wet bond lamination, this tunnel dryer provides consistent airflow and multi-zone temperature control to support aqueous adhesive curing. Its adjustable mounting and flotation capability ensure stable web handling during laminating operations.

TUNNEL: 16 Nozzles, 4 temp zones, flotation, adjustable mounting

TUNNEL: 16 Nozzles, 4 temp zones, flotation, adjustable mounting- COATER: Gravure

- WEB: 45 inch, Kraft Paper

- COATING: Aqueous adhesive

- PROCESS: Wet bond lamination

Custom Dryer Solutions

Not sure what dryer configuration would best fit your operations? Every converting line is different — and your dryer should be too. FlexAir designs custom tunnel dryer systems tailored to your press configuration, substrate, coating chemistry, and production goals.

Not sure what dryer configuration would best fit your operations? Every converting line is different — and your dryer should be too. FlexAir designs custom tunnel dryer systems tailored to your press configuration, substrate, coating chemistry, and production goals.

Contact our team to discuss or request a quote!

Bingham Flexo Services is a proud sales partner for FlexAir flexo dryer systems.

Markets & Applications

- Wide Web Flexo

- Corrugated Flexo

- Coating & Laminating

Contact Bingham Flexo Today

For More Information

630-879-7301

Or Email Us At

info@binghamflexoservices.com

For More Information

630-879-7301

Or Email Us At

info@binghamflexoservices.com